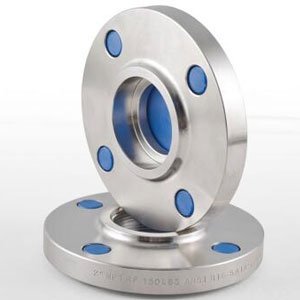

ASME B16.5 Socket Weld Flange Dimensions, Socket Weld Raised Face Flange, Socket Weld Pipe Flange Manufacturer in India

We as Metalfed Engineering are a prominent manufacturer and trader of Socket Weld Flanges, which are generally used in their annealed condition and have high workability and formability. Although still used in a variety of industries, many applications have shifted to these ASME B16.5 Socket Weld Pipe Flanges due to advances in fusion technology. Stainless Steel Socket Weld Reducing Flanges are generally used in the annealed condition and are characterized by their ease of manufacture and formability. Post-weld annealing is performed when it is necessary to dissolve the chromium carbide to provide maximum resistance to intergranular attack. This non-magnetic alloy is the most versatile and widely used of all steels. While other metals rust and corrode, Carbon Steel Socket Weld Flanges retain their finish and strength.

Socket Weld Orifice Flange is used for welded products that might be exposed to conditions that could cause intergranular corrosion in service. As with all austenitic stainless steels, the only heat treatment performed on these Monel Socket Weld Flanges is annealing. When welding this alloy, Socket Weld Raised Face Flange is recommended to use shielded fusion methods or resistors. Cold forming in Hastelloy Socket Weld Flanges will dramatically increase its hardness, and applications range from the stamping, spinning, and wire forming industries to the food and beverage, plumbing, cryogenic, and printing industries.

Exporter of ANSI B16.5 Socket Weld Reducing Flange, Socket Weld Flat Face Flange, Socket Weld Blind Flange, Socket Weld Orifice Flange, Socket Weld Ring Joint Flange in all Dimensions.

As a result, these Nickel Socket Weld Flanges can endure higher temperature, corrosive atmosphere, higher pressure, and a greater mechanical stress. Class 1500 Socket Weld Flange can be used for a variety of domestic and commercial applications and have excellent corrosion resistance.

Most Sold Products on Metalfed: Weld Neck Flange | Figure 8 Blank | Raised Face (RF) Flange | Flat Face (FF) | Nipoflange | Weldoflange

Largest Stockholder of JIS Socket Weld Flange, Series A and Series B Socket Weld Flange Welding, Socket Weld Flange Schedule 80 Sch 40, SAE 3000 Socket Weld Flange, ANSI B16.5 Class 150#, 300#, 600#, 900#, 1500#, 2500# Socket Weld Flanges, Socket Weld Flange PN16 at Best Prices.

ASME B16.5 / ASME B16.47 Socket Weld Flange Specifications

| Product Name: | Socket Weld Flange |

| Size Chart: | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Dimensions: | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Pressure Rating ANSI: | Class 150 LBS, 300 LBS, 400 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN: | PN6 PN10 PN16 PN25 PN40 PN64 / 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating/Surface Treatment: | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Connection Type/Flange Face Type: | RF-Raised Face, RTJ-Ring Type Joint, FF-Flat Face, LMF-Large Male-Female, LJF-Lap-Joint Face, SMF-Small Male-Female, Small Tongue, Large Tongue & Groove, Groove |

| Custom Flange/Special Design: | As per your drawing |

| Standards: | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, BS Flanges, ASME Flanges, EN Flanges, DIN Flanges, ASME/ANSI B16.5/16.36/16.47A/16.47B, GOST Flange, MSS SP44, ISO70051, BS1560-3.1, JISB2220, API7S-43, API7S-15, API605, EN1092 |

| Flange Test: | Direct-reading Spectrograph, X-ray detector, Hydrostatic testing machine, UI trasonic flaw detector, Magnetic particle detector |

| Flanges Equipment: | Press machine, Pushing Machine, Bending machine, electric bevelling machine, Sand-blasting machine, etc |

| Manufacturers of: | DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 B.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British Standard (BS) ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. ASTM A182 Socket Weld Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Test Certificates: | Third Party Inspection Report, 100% Radiography Test Report, Raw Materials Certificate, EN 10204/3.1B, etc. |

| Material Test Certificates (MTC): | As per EN 10204 3.1 and EN 10204 3.2, TC certifying NACE MR0103, NACE MR0175 |

| Uses & Applications: | Petrochemicals and acids, Nuclear Power, Heavy oil refineries, Bitumen upgraders, Offshore, Piping Projects etc. |

| Export Network: | Ireland, Oman, Dubai, Indonesia, Egypt, Singapore, Saudi & Arabia, Iran, Ukraine, Canada, USA, Brazil, Spain, Thailand, Korea, India, Peru, etc |

ANSI B16.5 Socket Weld Flange Materials and Grades

| Duplex Steel Socket Weld Flange: | ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61 |

| Super Duplex Socket Weld Flange: | ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61 |

| Stainless Steel Socket Weld Flange: | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| Nickel Alloys Socket Weld Flange: | ASTM SB564, SB160, SB472, SB162 – Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

| Alloys Socket Weld Flange: | Alloy 20, Alloy C, Alloy C276, Alloy B2 |

| Carbon Steel Socket Weld Flange: | STM / ASME A/SA 105 ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52 |

| Copper Alloys Socket Weld Flange: | ASTM SB 61, SB62, SB151, SB152 – UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200 |

| Low Temperature Steel Socket Weld Flange: | ASTM A350 LF2, LF3, LF6 |

| High Yield Socket Weld Flange: | ASTM A694 F42, F52, F60, F65, F70 |

| Alloy Steel Socket Weld Flange: | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Titanium Socket Weld Flange: | Gr1, Gr2, Gr3, Gr5, Gr7, Gr11 |

| Brass Socket Weld Flange: | 2604 / 3602 / H59 / H62 / etc. |

| Aluminium Socket Weld Flange: | 2017 / 5052 / 6063 / 6061 / 7075 etc. |

| Alloy 20 Socket Weld Flange: | ASME SB462 / ASTM B462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Nimonic Socket Weld Flange: | Nimonic 80A, Nimonic 75, Nimonic 90 |

| 254 SMO Socket Weld Flange: | ASME SA182 / ASTM A182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Other Socket Weld Flange Material: | Tin bronze, Alumunum bronze, Lead bronze |

Class 150 LBS Socket Weld Flange Dimensions

| Nominal size |

Outside Dia of Flange (D) |

Thick of Flange (B) |

Dia of Raised Face (G) |

Dia of Hub at Base (A) |

Length thru Hub (H) |

Dia of Bore (ID) |

Depth of Socket (F) |

No of Holes |

Dia of Holes (L) |

Dia of Bolts |

Dia of Bolt Circle (K) |

Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 88.9 | 11.2 | 35.1 | 30.2 | 15.7 | 22.4 | 9.7 | 4 | 15.7 | 1/2 | 60.5 | 0.5 |

| 3/4 | 98.6 | 12.7 | 42.9 | 38.1 | 15.7 | 27.7 | 11.2 | 4 | 15.7 | 1/2 | 69.9 | 1 |

| 1 | 108 | 14.2 | 50.8 | 49.3 | 17.5 | 34.5 | 12.7 | 4 | 15.7 | 1/2 | 79.2 | 1 |

| 1-1/4 | 117.3 | 15.7 | 63.5 | 58.7 | 20.6 | 43.2 | 14.2 | 4 | 15.7 | 1/2 | 88.9 | 1 |

| 1-1/2 | 127 | 17.5 | 73.2 | 65 | 22.4 | 49.5 | 15.7 | 4 | 15.7 | 1/2 | 98.6 | 1 |

| 2 | 152.4 | 19.1 | 91.9 | 77.7 | 25.4 | 62 | 17.5 | 4 | 19.1 | 5/8 | 120.7 | 2 |

| 2-1/2 | 177.8 | 22.4 | 104.6 | 90.4 | 28.4 | 74.7 | 19.1 | 4 | 19.1 | 5/8 | 139.7 | 3 |

| 3 | 190.5 | 23.9 | 127 | 108 | 30.2 | 90.7 | 20.6 | 4 | 19.1 | 5/8 | 152.4 | 4 |

| 3-1/2 | 215.9 | 23.9 | 139.7 | 122.2 | 31.8 | 103.4 | 8 | 19.1 | 5/8 | 177.8 | 5 | |

| 4 | 228.6 | 23.9 | 157.2 | 134.9 | 33.3 | 116.1 | 8 | 19.1 | 5/8 | 190.5 | 6 | |

| 5 | 254 | 23.9 | 185.7 | 163.6 | 36.6 | 143.8 | 8 | 22.4 | 3/4 | 215.9 | 7 | |

| 6 | 279.4 | 25.4 | 215.9 | 192 | 39.6 | 170.7 | 8 | 22.4 | 3/4 | 241.3 | 9 | |

| 8 | 342.9 | 28.4 | 269.7 | 246.1 | 44.5 | 221.5 | 8 | 22.4 | 3/4 | 298.5 | 14 | |

| 10 | 406.4 | 30.2 | 323.9 | 304.8 | 49.3 | 276.4 | 12 | 25.4 | 7/8 | 362 | 20 | |

| 12 | 482.6 | 31.8 | 381 | 365.3 | 55.6 | 327.2 | 12 | 25.4 | 7/8 | 431.8 | 29 | |

| 14 | 533.4 | 35.1 | 412.8 | 400.1 | 57.2 | 359.2 | 12 | 28.4 | 1 | 476.3 | 41 | |

| 16 | 596.9 | 36.6 | 469.9 | 457.2 | 63.5 | 410.5 | 16 | 28.4 | 1 | 539.8 | 44 | |

| 18 | 635 | 39.6 | 533.4 | 505 | 68.3 | 461.8 | 16 | 31.8 | 1-1/8 | 577.9 | 59 | |

| 20 | 698.5 | 42.9 | 584.2 | 558.8 | 73.2 | 513.1 | 20 | 31.8 | 1-1/8 | 635 | 75 | |

| 24 | 812.8 | 47.8 | 692.2 | 663.4 | 82.6 | 616 | 20 | 35.1 | 1-1/4 | 749.3 | 100 |

Class 300 LBS Socket Weld Flange Dimensions

| Nominal size |

Outside Dia of Flange (D) |

Thick of Flange (B) |

Dia of Raised Face (G) |

Dia of Hub at Base (A) |

Length thru Hub (H) |

Dia of Bore (ID) |

Depth of Socket (F) |

No of Holes |

Dia of Holes (L) |

Dia of Bolts |

Dia of Bolt Circle (K) |

Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 95.3 | 14.2 | 35.1 | 38.1 | 22.4 | 22.4 | 9.7 | 4 | 15.7 | 1/2 | 66.5 | 1 |

| 3/4 | 117.3 | 15.7 | 42.9 | 47.8 | 25.4 | 27.7 | 11.2 | 4 | 19.1 | 5/8 | 82.6 | 1 |

| 1 | 124 | 17.5 | 50.8 | 53.8 | 26.9 | 34.5 | 12.7 | 4 | 19.1 | 5/8 | 88.9 | 1 |

| 1-1/4 | 133.4 | 19.1 | 63.5 | 63.5 | 26.9 | 43.2 | 14.2 | 4 | 19.1 | 5/8 | 98.6 | 2 |

| 1-1/2 | 155.4 | 20.6 | 73.2 | 69.9 | 30.2 | 49.5 | 15.7 | 4 | 22.4 | 3/4 | 114.3 | 3 |

| 2 | 165.1 | 22.4 | 91.9 | 84.1 | 33.3 | 62 | 17.5 | 8 | 19.1 | 5/8 | 127 | 3 |

| 2-1/2 | 190.5 | 25.4 | 104.6 | 100.1 | 38.1 | 74.7 | 19.1 | 8 | 22.4 | 3/4 | 149.4 | 5 |

| 3 | 209.6 | 28.4 | 127 | 117.3 | 42.9 | 90.7 | 20.6 | 8 | 22.4 | 3/4 | 168.1 | 6 |

| 3-1/2 | 228.6 | 30.2 | 139.7 | 133.4 | 44.5 | 103.4 | 8 | 22.4 | 3/4 | 184.2 | 8 | |

| 4 | 254 | 31.8 | 157.2 | 146.1 | 47.8 | 116.1 | 8 | 22.4 | 3/4 | 200.2 | 10 | |

| 5 | 279.4 | 35.1 | 185.7 | 177.8 | 50.8 | 143.8 | 8 | 22.4 | 3/4 | 235 | 13 | |

| 6 | 317.5 | 36.6 | 215.9 | 206.2 | 52.3 | 170.7 | 12 | 22.4 | 3/4 | 269.7 | 18 | |

| 8 | 381 | 41.1 | 269.7 | 260.4 | 62 | 221.5 | 12 | 25.4 | 7/8 | 330.2 | 26 | |

| 10 | 444.5 | 47.8 | 323.9 | 320.5 | 66.5 | 276.4 | 16 | 28.4 | 1 | 387.4 | 37 | |

| 12 | 520.7 | 50.8 | 381 | 374.7 | 73.2 | 327.2 | 16 | 31.8 | 1-1/8 | 450.9 | 52 | |

| 14 | 584.2 | 53.8 | 412.8 | 425.5 | 76.2 | 359.2 | 16 | 31.8 | 1-1/8 | 514.4 | 75 | |

| 16 | 647.7 | 57.2 | 469.9 | 482.6 | 82.6 | 410.5 | 20 | 35.1 | 1-1/4 | 571.5 | 86 | |

| 18 | 711.2 | 60.5 | 533.4 | 533.4 | 88.9 | 461.8 | 24 | 35.1 | 1-1/4 | 628.7 | 113 | |

| 20 | 774.7 | 63.5 | 584.2 | 587.2 | 95.3 | 513.1 | 24 | 35.1 | 1-1/4 | 685.8 | 143 | |

| 24 | 914.4 | 69.9 | 692.2 | 701.5 | 106.4 | 616 | 24 | 41.1 | 1-1/2 | 812.8 | 215 |

Class 600 LBS Socket Weld Flange Dimensions

| Nominal size |

Outside Dia of Flange (D) |

Thick of Flange (B) |

Dia of Raised Face (G) |

Dia of Hub at Base (A) |

Length thru Hub (H) |

Dia of Bore (ID) |

Depth of Socket (F) |

No of Holes |

Dia of Holes (L) |

Dia of Bolts |

Dia of Bolt Circle (K) |

Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 95.3 | 14.2 | 35.1 | 38.1 | 22.4 | 22.4 | 9.7 | 4 | 15.7 | 1/2 | 66.5 | 1 |

| 3/4 | 117.3 | 15.7 | 42.9 | 47.8 | 25.4 | 27.7 | 11.2 | 4 | 19.1 | 5/8 | 82.6 | 1 |

| 1 | 124 | 17.5 | 50.8 | 53.8 | 26.9 | 34.5 | 12.7 | 4 | 19.1 | 5/8 | 88.9 | 2 |

| 1-1/4 | 133.4 | 20.6 | 63.5 | 63.5 | 28.4 | 43.2 | 14.2 | 4 | 19.1 | 5/8 | 98.6 | 2 |

| 1-1/2 | 155.4 | 22.4 | 73.2 | 69.9 | 31.8 | 49.5 | 15.7 | 4 | 22.4 | 3/4 | 114.3 | 3 |

| 2 | 165.1 | 25.4 | 91.9 | 84.1 | 36.6 | 62 | 17.5 | 8 | 19.1 | 5/8 | 127 | 4 |

| 2-1/2 | 190.5 | 28.4 | 104.6 | 100.1 | 41.1 | 74.7 | 19.1 | 8 | 22.4 | 3/4 | 149.4 | 6 |

| 3 | 209.6 | 31.8 | 127 | 117.3 | 46 | 90.7 | 20.6 | 8 | 22.4 | 3/4 | 168.1 | 7 |

| 3-1/2 | 228.6 | 35.1 | 139.7 | 133.4 | 49.3 | 103.4 | 8 | 25.4 | 7/8 | 184.2 | 10 | |

| 4 | 273.1 | 38.1 | 157.2 | 152.4 | 53.8 | 116.1 | 8 | 25.4 | 7/8 | 215.9 | 17 | |

| 5 | 330.2 | 44.5 | 185.7 | 189 | 60.5 | 143.8 | 8 | 28.4 | 1 | 266.7 | 29 | |

| 6 | 355.6 | 47.8 | 215.9 | 222.3 | 66.5 | 170.7 | 12 | 28.4 | 1 | 292.1 | 36 | |

| 8 | 419.1 | 55.6 | 269.7 | 273.1 | 76.2 | 221.5 | 12 | 31.8 | 1-1/8 | 349.3 | 52 | |

| 10 | 508 | 63.5 | 323.9 | 342.9 | 85.9 | 276.4 | 16 | 35.1 | 1-1/4 | 431.8 | 77 | |

| 12 | 558.8 | 66.5 | 381 | 400.1 | 91.9 | 327.2 | 20 | 35.1 | 1-1/4 | 489 | 91 | |

| 14 | 603.3 | 69.9 | 412.8 | 431.8 | 93.7 | 359.2 | 20 | 38.1 | 1-3/8 | 527.1 | 104 | |

| 16 | 685.8 | 76.2 | 469.9 | 495.3 | 106.4 | 410.5 | 20 | 41.1 | 1-1/2 | 603.3 | 150 | |

| 18 | 743 | 82.6 | 533.4 | 546.1 | 117.3 | 461.8 | 20 | 44.5 | 1-5/8 | 654.1 | 181 | |

| 20 | 812.8 | 88.9 | 584.2 | 609.6 | 127 | 513.1 | 24 | 44.5 | 1-5/8 | 723.9 | 231 | |

| 24 | 939.8 | 101.6 | 692.2 | 717.6 | 139.7 | 616 | 24 | 50.8 | 1-7/8 | 838.2 | 331 |

Class 1500 LBS Socket Weld Flange Dimensions

| Nominal size |

Outside Dia of Flange (D) |

Thick of Flange (B) |

Dia of Raised Face (G) |

Dia of Hub at Base (A) |

Length thru Hub (H) |

Dia of Bore (ID) |

Depth of Socket (F) |

No of Holes |

Dia of Holes (L) |

Dia of Bolts |

Dia of Bolt Circle (K) |

Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 120.7 | 22.4 | 35.1 | 38.1 | 31.8 | 22.4 | 9.7 | 4 | 22.4 | 3/4 | 82.6 | 2 |

| 3/4 | 130 | 25.4 | 42.9 | 44.5 | 35.1 | 27.7 | 11.2 | 4 | 22.4 | 3/4 | 88.9 | 2 |

| 1 | 149.4 | 28.4 | 50.8 | 52.3 | 41.1 | 34.5 | 12.7 | 4 | 25.4 | 7/8 | 101.6 | 4 |

| 1-1/4 | 158.8 | 28.4 | 63.5 | 63.5 | 41.1 | 43.2 | 14.2 | 4 | 25.4 | 7/8 | 111.3 | 4 |

| 1-1/2 | 177.8 | 31.8 | 73.2 | 69.9 | 44.5 | 49.5 | 15.7 | 4 | 28.4 | 1 | 124 | 5 |

| 2 | 215.9 | 38.1 | 91.9 | 104.6 | 57.2 | 62 | 17.5 | 8 | 25.4 | 7/8 | 165.1 | 11 |

| 2-1/2 | 244.3 | 41.1 | 104.6 | 124 | 63.5 | 74.7 | 8 | 19.1 | 28.4 | 1 | 190.5 | 16 |

| 3 | 266.7 | 47.8 | 127 | 133.4 | 73.2 | 8 | 31.8 | 1-1/8 | 203.2 | 22 | ||

| 4 | 311.2 | 53.8 | 157.2 | 162.1 | 90.4 | 8 | 35.1 | 1-1/4 | 241.3 | 33 | ||

| 5 | 374.7 | 73.2 | 185.7 | 196.9 | 104.6 | 8 | 41.1 | 1-1/2 | 292.1 | 59 | ||

| 6 | 393.7 | 82.6 | 215.9 | 228.6 | 119.1 | 12 | 38.1 | 1-3/8 | 317.5 | 75 | ||

| 8 | 482.6 | 91.9 | 269.7 | 292.1 | 142.7 | 12 | 44.5 | 1-5/8 | 393.7 | 118 | ||

| 10 | 584.2 | 108 | 323.9 | 368.3 | 158.8 | 12 | 50.8 | 1-7/8 | 482.6 | 197 | ||

| 12 | 673.1 | 124 | 381 | 450.9 | 180.8 | 16 | 53.8 | 2 | 571.5 | 263 | ||

| 14 | 749.3 | 133.4 | 412.8 | 495.3 | 16 | 60.5 | 2-1/4 | 635 | ||||

| 16 | 825.5 | 146.1 | 469.9 | 552.5 | 16 | 66.5 | 2-1/2 | 704.9 | ||||

| 18 | 914.4 | 162.1 | 533.4 | 596.9 | 16 | 73.2 | 2-3/4 | 774.7 | ||||

| 20 | 984.3 | 177.8 | 584.2 | 641.4 | 16 | 79.2 | 3 | 831.9 | ||||

| 24 | 1168.4 | 203.2 | 692.2 | 762 | 16 | 91.9 | 3-1/2 | 990.6 |

ASME B16.5 Socket Weld Flange Dimensions & Stud Bolts

NPS 1/2 – ID = 22.3 – F = 9.5

| CLass | 150 | 300 | 600 | 900 | 1500 | 2500 |

| DIA A |

30 | 38 | 38 | … | 38 | … |

| DIA D |

90 | 95 | 95 | … | 120 | … |

| THK B |

9.6 | 12.7 | 14.3 | … | 22.3 | … |

| 11.2 | 14.3 | 20.7 | … | 28.7 | … | |

| DIA G |

35.1 | 35.1 | 35.1 | … | 35.1 | … |

| DIA K |

60.3 | 66.7 | 66.7 | … | 82.6 | … |

| H | 14 | 21 | 22 | … | 32 | … |

| 15.6 | 22.6 | 28.4 | … | 38.4 | … | |

| NO. L |

4 | 4 | 4 | … | 4 | … |

| DIA L |

15.9 | 15.9 | 15.9 | … | 22.2 | … |

| Stud Bolts Diameter x Length | ||||||

| DIA (in) |

1/2 | 1/2 | 1/2 | … | 3/4 | … |

| Len mm |

55 | 65 | 75 | … | 110 | … |

| Other Diameters | |||||||

| NPS | 1/2 | 3/4 | 1 | 1¼ | 1½ | 2 | 2½ |

Notes:

- Dimensions are in millimeters unless otherwise indicated.

- The length of the Stud Bolt does not include the height of the chamfers (points).

- ID2 = Depending on the wall thickness of the pipe, must be specified by the purchaser.

Types of ANSI B16.5 Socket Weld Flange

- 2 socket weld flanges

- ASME B16.5 socket weld flanges

- socket weld reducing Flanges

- sae 3000 socket weld flanges

- copper socket weld flanges

- socket weld flanges class 300

- reducing socket weld flange

- socket weld orifice flange

- socket weld pipe flange

- socket weld raised face flange

- socket weld flat face flange

- socket weld blind flange

- class 150 socket weld flange

- socket weld flange pn 16

- 12 socket weld flange

- 1/2 socket weld flange

- 150# socket weld flange

- Aluminium socket weld flange

- 150 LB socket weld flange

- 300 LB socket weld flange

- socket weld RTJ flange

- reducing socket weld flange

- socket weld flange sch 80

- stainless steel socket weld flange

- socket weld flange welding

- carbon steel socket weld flange

- class 600 socket weld flange

- class 900 socket weld flange

- ss socket weld flange sch 40

- 2 inch socket weld flange

- 2500# socket weld flange

- jis socket weld flange

- socket weld ring type joint flange

Socket Weld Flange Applications & Industries

We are well-known prestigious Manufacturers, Exporters, and Suppliers of high quality ASME B16.5 Socket Weld Flange. We supply Socket Weld Pipe Flange to customers in various industries including chemical, pharmaceutical, petrochemical, power, engineering and various other industrial applications. Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, Third Party Inspection Report and 100% Radiography Test Report.

Ready Stock of Socket Weld Flange Export to

AfricaAlgeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cabo Verde, Cameroon, Central African Republic (CAR), Chad, Comoros, The Democratic Republic of the Congo, Republic of the Congo, Cote d’Ivoire, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea-Bissau, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

EuropeAlbania, Andorra, Armenia, Austria, Azerbaijan, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Georgia, Germany, Greece, Hungary, Iceland, Ireland, Italy, Kazakhstan, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, San Marino, Serbia, Slovakia, Slovenia, Spain, Sweden, Turkey, Ukraine, United Kingdom, Vatican City

AmericaAntigua and Barbuda, Bahamas, Barbados, Belize, Canada, Costa Rica, Cuba, Dominica, Dominican Republic, El Salvador, Grenada, Guatemala, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, United States of America, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela

Asia/OceaniaAfghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, Cyprus, Georgia, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Laos, Lebanon, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, North Korea, Oman, Pakistan, Palestine, Philippines, Qatar, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Timor-Leste, Turkey, Turkmenistan, United Arab Emirates (UAE), Uzbekistan, Vietnam, Yemen, Australia, Fiji, Kiribati, Marshall Islands, Micronesia, Nauru, New Zealand, Palau, Papua New Guinea, Samoa, Solomon Islands, Tonga, Tuvalu, Vanuatu

Please send us the complete details of Socket Weld Flange requirement. We offer ANSI B16.5 Socket Weld Flange, and Socket Weld Reducing Flanges which are accurately designed to provide satisfaction to our customers. We are assisted by a team of skilled professionals, who support us in all our career activities right from a realization of raw material to testing and final dispatch of these Class 150#, 300#, 400#, 600#, 900#, 1500#, 2500#, Socket Weld Flange at our valuable customers end. Buy Socket Weld Flangeat a cheap price from us.

sales@metalfed.com | +91 9137898594 | Quotation Form | Reach Us