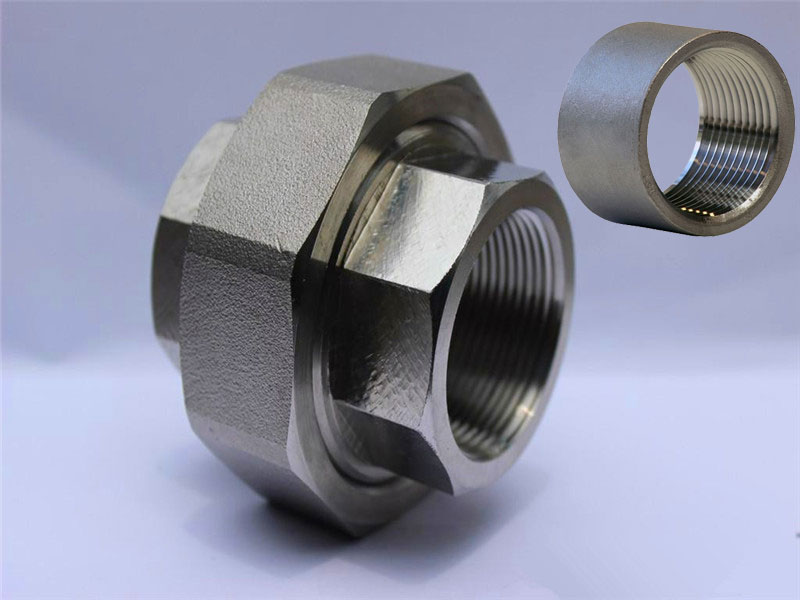

The basic difference between a threaded union and threaded coupling is that threaded unions are made for joining and disassembling a part of a piping system such as a steam trap or control valve, etc for maintenance or replacement purpose. A coupling is used for joining pipe to pipe or pipe to a swedge.

Pipe Coupling and Unions are available in both types of forged fittings namely threaded and socket weld fittings. Pipe coupling are available in the form of Full Coupling, Half Coupling, and Reducing Coupling.

Couplings provide more robust joints in high-pressure applications whereas, in practice, unions are best suited to low-pressure applications.

More information of Pipe Unions:

- Materials: stainless steel, carbon steel, alloy steel, brass, etc.

- Connection Forms: threaded and socket welding connection.

- Manufacturing Standards: MSS SP 83, ASME B16.11.

- Types: there are different diameters and equal diameters of threaded unions.

- Product Link: SOCKET WELD COUPLING, SOCKET WELD UNION.

More information of Pipe Couplings:

- Materials: alloy steel, stainless steel, carbon steel, etc.

- Connection Methods: welding, socket, threaded connection, etc.

- Manufacturing Standards: ASME B16.11, BS 3799, GB/T14383, DIN2986, ASME B1.20.1, BS10241.

- Types: Full Coupling, Half Coupling, and Reducing Coupling.

- Product Link: THREADED COUPLING, THREADED UNION.

Pipe coupling is a lower-cost item and the union is a higher-cost item. When you need the ability to disassemble the piping for the removal of an item then you must use the higher-cost unions. When you are just joining pipe you would want to use the lowest cost item couplings.

Venezuela

Venezuela Myanmar

Myanmar Sri Lanka

Sri Lanka Belgium

Belgium Czechia

Czechia Greece

Greece Mexico

Mexico Tobago

Tobago Brazil

Brazil Chile

Chile France

France Colombia

Colombia South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Iraq

Iraq Ukraine

Ukraine Romania

Romania Cyprus

Cyprus Angola

Angola Norway

Norway USA

USA Saudi Arabia

Saudi Arabia Kuwait

Kuwait Thailand

Thailand South Korea

South Korea Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines China

China UK

UK India

India Japan

Japan Russia

Russia Canada

Canada Iran

Iran Turkey

Turkey Morocco

Morocco Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal