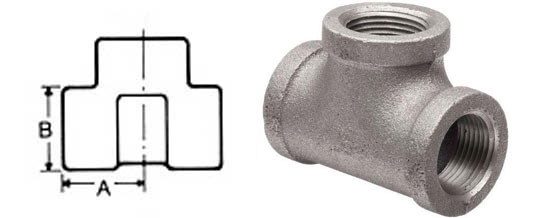

Exporter of Threaded Reducing Tee ASME B16.11, Threaded Lateral Tee Dimensions

ASME B16.11 Threaded Reducing Tee must be annealed after forging.Threaded Lateral Tee is mainly used when the production includes extensive processing on screwing machines. While sulphur improves machinability, it also causes a reduction in corrosion resistance and a slight reduction in toughness. However, the corrosion resistance of these Stainless Steel Threaded Tee is still good in temperate environments where annealing to grind is required if necessary. The durability of these accessories facilitates manufacturing and prevents product contamination. It is used at 1010 degrees C – 1120 degrees C (1850 degrees F – 2048 degrees F) for optimum glow heat and is rapidly air or water quenched.

We as Metalfed Engineering are a standard manufacturer and supplier of Forged Threaded Reducing Tee / Forged Threaded Lateral Tee , which is the unrestricted machining amendment of the basic nickel and chromium alloy. It is subject to pitting and crevice corrosion in chloride-containing environments above 60 degrees C. Inconel Alloy Forged Threaded Reducing Tee Fittings shows good oxidation resistance in continuous service up to 870 degrees C and in intermittent service up to 760 degrees C. It is considered the most versatile and common austenite steel, and it’s also more cost-effective. Unlike other steel, which begins to rust when exposed to air and moisture, Monel Alloy Forged Threaded Lateral Tee Fittings does not easily corrode, rust, or discolor in normal environments. It has wonderful corrosion resistance properties but is prone to pitting in hot chloride environments.

Check ASME B16.11 Threaded Tee Dimensions, Stainless Steel Threaded Tee, Threaded Brass Tee Pressure Rating, BSP Threaded Tee Weight, NPT Threaded Tee Class 3000 Price List, JIS Threaded Tee, MS Threaded Tee Manufacturers in India.

Renowed Threaded Reducing Tee Manufacturers in India, Threaded Copper Tee Stockist, Aluminum Threaded Tee Stockholder, Duplex Threaded Equal Tee, Galvanized Threaded Tee, Threaded Straight Tee, 2000# Threaded Unequal Tee, 3000# Threaded Union Tee, 6000# Threaded Tee Dimensions.

ASME B16.11 Threaded Tee Specifications/Production Range

Size Range:

1/8″~4″ (DN6~DN100) (Screwed-Threaded)

Dimensions:

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Form

Threaded/Screwed Reducing Tee, Lateral Tee.

Pressure Class:

2000 LBS, 3000 LBS, 6000 LBS.

Thread Standards:

NPT, BSPT, BSPP.

Value Added Services:

Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering.

ASME B16.11 Threaded Reducing Tee Dimensions- Class 2000

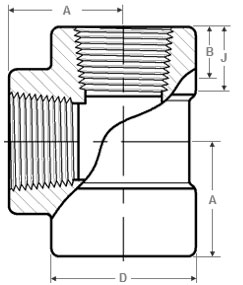

Dimensions are in millimeters unless otherwise indicated. Dimension B is minimum length of perfect thread. The length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than J.

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1¼ | 17 | 18 | 56 | 44 | 3.89 |

| 1½ | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2½ | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

ASME B16.11 Threaded Tee Dimensions- Class 3000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1¼ | 17 | 18 | 62 | 51 | 5.28 |

| 1½ | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2½ | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

ASME B16.11 Threaded Tee Dimensions- Class 6000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1¼ | 17 | 18 | 75 | 60 | 10.59 |

| 1½ | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2½ | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

ASME B16.11 Threaded Reducing Tee Weight Chart

| Class 2000 | Nominal Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.740 | 1.058 | 1.375 | 1.740 | 2.883 | 7.750 | 11.313 | 19.125 | |

Class 3000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.250 | 0.290 | 0.500 | 0.750 | 1.188 | 1.988 | 2.235 | 3.000 | 4.930 | 7.375 | 13.588 | 19.063 | |

Class 6000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.250 | 0.640 | 0.500 | 1.438 | 2.188 | 2.785 | 4.688 | 5.750 | 9.500 | 15.000 | 30.563 | – | |

ASME B 16.11 Threaded Tee Manufacturing Standards

| ASME | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN | EN10253-1, EN10253-2 |

Fogred Threaded Tee Available Grades

| Stainless Steel Threaded Tee: | The material for forged stainless steel Threaded Tee conforms to ASME A182 The dimensions for forged stainless steel Threaded Tee conform to ASME B16.11 ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Carbon Steel Threaded Tee: |

The material for forged carbon steel Threaded Tee conforms to the requirements of ASTM/ASME A105/SA105 The dimensions for forged carbon steel Threaded Tee conform to ASME B16.11 Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB |

| Other Materials: | DupleX, Super Duplex, Alloy Steel, Monel, Nickel, Inconel, Incoloy, Hastelloy, Copper, Alloy 20, SMO 254, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminium, Zinc, Lead, etc. |

ASME B 16.11 Threaded Tee Available Stock

- BSP Threaded Tee

- SS NPT Threaded Tee

- Threaded Tee Stainless Steel

- Carbon Steel Threaded Tee

- ASME B16.11 Threaded Tee Fitting

- ASTM A234 Threaded Tee

- 3 Inch Threaded Reducing Tee

- 3000lb Threaded Reducing Tee

- JIS Threaded Lateral Tee

- 300# Threaded Reducing Tee

- SCH 40 Threaded Tee

- 3000 LB Threaded Tee

- Threaded Reducing Tee

- MS Threaded Unequal Tee

- 3/4 Threaded Lateral Tee

- 6000# Threaded Reducing Tee

- Hastelloy Threaded Tee

- Schedule 80 Threaded Tee

- 4 Inch Copper Threaded Tee

- Class 6000 Threaded Tee

- 2000# Threaded Reducing Tee

- Nickel Alloy Threaded Tee

- 3000 psi Threaded Tee

- Aluminium Threaded Tee

- Schedule 160 Threaded Reducing Tee

- SCH 10 SS Threaded Straight Tee

- ASTM A403 Threaded Straight Tee

- SCH 80 Reducing Tee

- Duplex Threaded Tee

- Class 3000 Threaded Pipe Tee

- Super Duplex Threaded Tee

- Galvanized Threaded Tee

- Brass Threaded Reducing Tee

- Aluminium Threaded Reducing Tee

- Copper Nickel Threaded Tee

- Class 3000 Threaded Tee

- 6000 LB Threaded Tee

- Threaded Equal Tee

- 1 SS Threaded Tee Fitting

- 1/2 Threaded Tee Fitting

- 6 inch Threaded Tee Fitting

- 2 Threaded Lateral Tee

ASME B 16.11 Threaded Tee – Applications & Industries

We are well-known prestigious exporter and supplier of high quality ASME B16.11 Threaded Reducing Tee and Threaded Lateral Tee. We supply ASTM A105 Threaded Tee to customers in various industries including chemical, pharmaceutical, petrochemical, power, engineering and various other industrial applications. Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, Third Party Inspection Report and 100% Radiography Test Report.

Ready Stock of Threaded Pipe Tee Export to

Africa Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cabo Verde, Cameroon, Central African Republic (CAR), Chad, Comoros, The Democratic Republic of the Congo, Republic of the Congo, Cote d’Ivoire, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea-Bissau, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

Europe,Albania, Finland, France, Ireland, Italy, Andorra, Armenia, Austria, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Georgia, Germany, Denmark, Estonia, Kazakhstan, Kosovo, Greece, Hungary, Iceland, Latvia, Liechtenstein, Azerbaijan, Belarus, Belgium, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, San Marino, Serbia, Slovakia, Slovenia, Spain, Sweden, Turkey, Ukraine, United Kingdom, Vatican City

AmericaAntigua and Barbuda, Bahamas, Barbados, Belize, Canada, Costa Rica, Cuba, Dominica, Dominican Republic, El Salvador, Grenada, Guatemala, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, United States of America, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela

Asia/OceaniaAfghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, Cyprus, Georgia, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Laos, Lebanon, Malaysia, Maldives, Mongolia, Myanmar (Burma), Oman, Pakistan, Palestine, Philippines, Qatar, Nepal, North Korea, Russia, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Timor-Leste, Turkey, Turkmenistan, United Arab Emirates (UAE), Uzbekistan, Vietnam, Yemen, Australia, Fiji, Kiribati, Marshall Islands, Micronesia, Nauru, New Zealand, Palau, Papua New Guinea, Samoa, Solomon Islands, Tonga, Tuvalu, Vanuatu

Please send us the complete details of NPT Threaded Tee requirement. We offer ASME B16.11 Threaded Reducing Tee, and MSS SP-95 Threaded Lateral Tee which are accurately designed to provide satisfaction to our customers. We are assisted by a team of skilled professionals, who support us in all our career activities right from a realization of raw material to testing and final dispatch of these Threaded Pipe Tee at our valuable customers end. Buy MSS SP-79 NPT Threaded Reducing Tee at reasonable price from us.

sales@metalfed.com | +91 9137898594 | Quotation Form | Reach Us

Venezuela

Venezuela Myanmar

Myanmar Sri Lanka

Sri Lanka Belgium

Belgium Czechia

Czechia Greece

Greece Mexico

Mexico Tobago

Tobago Brazil

Brazil Chile

Chile France

France Colombia

Colombia South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Iraq

Iraq Ukraine

Ukraine Romania

Romania Cyprus

Cyprus Angola

Angola Norway

Norway USA

USA Saudi Arabia

Saudi Arabia Kuwait

Kuwait Thailand

Thailand South Korea

South Korea Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines China

China UK

UK India

India Japan

Japan Russia

Russia Canada

Canada Iran

Iran Turkey

Turkey Morocco

Morocco Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal