April 9, 2023

By Metalfed Engineering

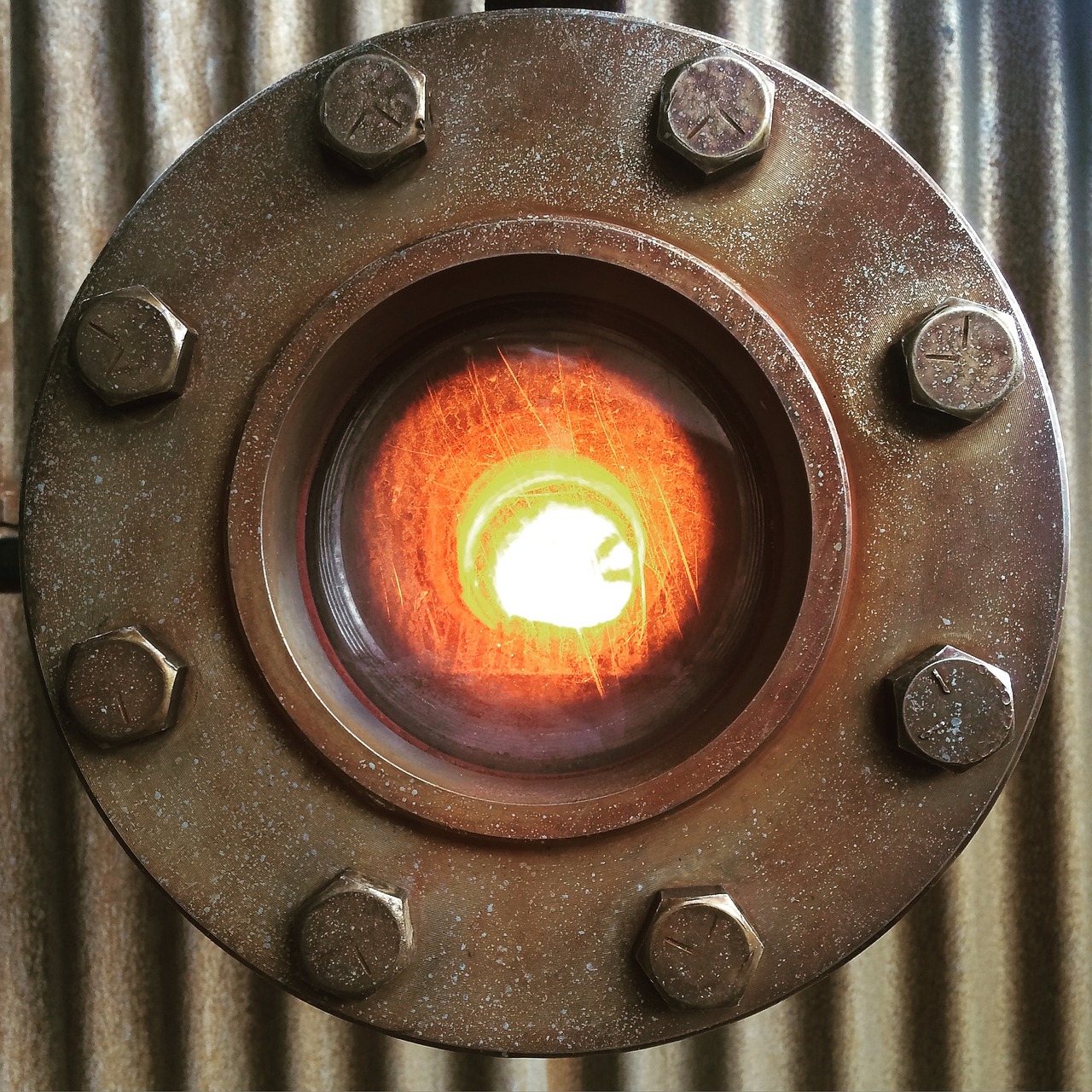

Flange Manufacturing, Quality Control in Steel Fitting

Quality Control in Steel Fitting and Flange Manufacturing

The Importance of Quality control is critical in steel fitting and flange manufacturing for several reasons:

- Ensuring Consistent Quality: Quality control procedures are put in place to ensure that all products are produced to a consistently high standard. This is important to maintain the reliability and safety of steel fittings and flanges.

- Meeting Customer Requirements: Quality control procedures ensure that products meet the requirements of the customers. This includes dimensional accuracy, material quality, and performance specifications.

- Minimizing Defects: Quality control procedures can detect defects early on in the manufacturing process, preventing them from being passed on to the customer. This reduces the likelihood of product failures and the costs associated with repairing or replacing defective products.

- Improving Efficiency: Quality control procedures help to identify areas for improvement in the manufacturing process, which can lead to increased efficiency, reduced waste, and lower production costs.

- Complying with Regulations: Quality control procedures ensure that products comply with industry standards and regulations. This is particularly important for industries such as oil and gas, where safety is critical.

- Enhancing Brand Reputation: Quality control procedures help to maintain the reputation of the brand by ensuring that products are consistently reliable and safe. This can lead to increased customer loyalty and repeat business.

Overall, quality control is essential in steel fitting and flange manufacturing to ensure that products meet customer requirements, comply with regulations, and maintain a high level of safety and reliability.

Venezuela

Venezuela Myanmar

Myanmar Sri Lanka

Sri Lanka Belgium

Belgium Czechia

Czechia Greece

Greece Mexico

Mexico Tobago

Tobago Brazil

Brazil Chile

Chile France

France Colombia

Colombia South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Poland

Poland Bangladesh

Bangladesh Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Iraq

Iraq Ukraine

Ukraine Romania

Romania Cyprus

Cyprus Angola

Angola Norway

Norway USA

USA Saudi Arabia

Saudi Arabia Kuwait

Kuwait Thailand

Thailand South Korea

South Korea Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines China

China UK

UK India

India Japan

Japan Russia

Russia Canada

Canada Iran

Iran Turkey

Turkey Morocco

Morocco Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal